Installation of a Kettle Chip Line

Premier Technology’s project scope was to install a kettle chip line from raw materials through to packaging, utilizing existing rooms whose infrastructure was not setup for this to happen. Initial site visit was in December. After developing several concepts to meet the customer’s needs, final drawings were completed in late December. Demolition began the first week of February and construction started in late February. Final installation was complete June.

Demolition:

Premier’s crew demoed over 200cy of concrete, installed over 700ft of drain line, and lowered the production room floor by 18” in order to create enough space for the 4 MOK-300 chip kettles. Our crew cut 6 doorways for access to 6 new oil tanks, demoed 3 oil tanks, a caustic tank, and a rollup door. They also removed an existing oil tank access building.

Construction:

Installed a new truck dumper which included pouring 25cy of concrete wall, 156cy of concrete pad, and 15cy of concrete for truck approach. Installed a new sump and piped into existing drain line. Installed 5 new floor drains. Poured new floor sloping to new drains. Poured 42cy of concrete for the new potato bin room along with installing 2 new floor drains. Poured 37cy of concrete for the exterior oil tanks. Also poured 24cy of concrete for a 30,000 gallon water tank pad. Installed new doors, handrails and walls. Applied Silikal floor coating to all the newly poured interior concrete floors.

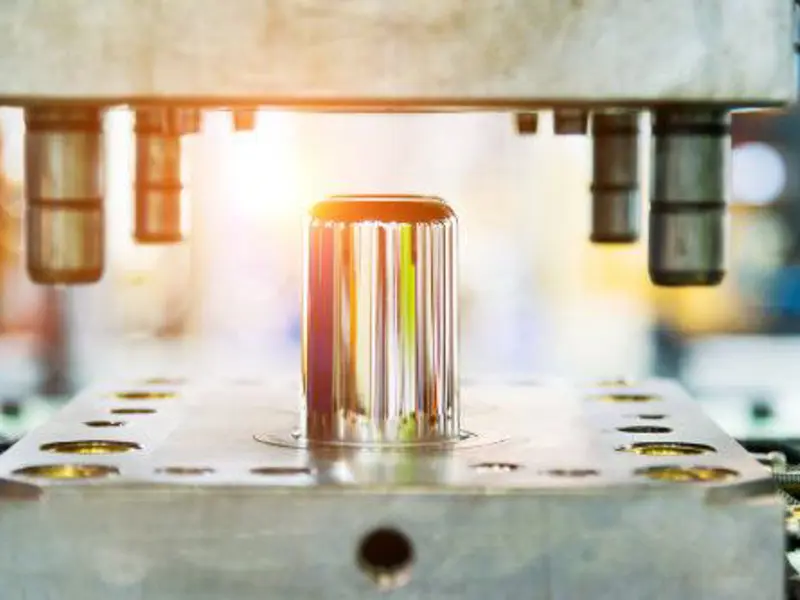

Equipment Installation:

Designed and installed 3 cableveys to carry finished kettle chips from production to the existing packaging area, approximately 420’ away. Installed 6 new horizontal oil tanks, DAF filter, screen assembly and tank, sludge tanks, chemical stands and pump skids. Installed the truck dump system and its hydraulic oil system. Various conveyors, 2 large potato storage bins, platforms, flume, pumps, peelers, 4 kettles, slicers, hoods, stacks, roof repair, waste oil tanks, CIP system and all water, oil, air piping. Installed electrical panels, all equipment control panels, new led lights and all wiring to power up all equipment.